Learn: The CO2 Regulator and Aquarium CO2 System

Carbon dioxide is a chemical compound composed of two oxygen atoms bonded to a single carbon atom (O=C=O). During photosynthesis, terrestrial and aquatic plants use carbon dioxide and water, removed from the atmosphere and combined with light energy to produce oxygen and sugars. These sugars may then be consumed in respiration or used to produce polysaccharides, complex carbohydrates, such as starch, cellulose, proteins, and other organic compounds required for plant growth and development.

In the planted aquarium ecosystem, carbon dioxide is introduced through the use of a CO2 regulator in combination with additional equipment. Carbon Dioxide (CO2) is fundamental to the function and success of the planted tank.

CO2 Cylinder – Carbon dioxide (CO2) in a cylinder exists primarily in the form of liquid CO2, only the head space of the tank contains gas. The liquid allows the cylinder to maintain a constant and high pressure; as long as the cylinder contains any amount of the liquid CO2 the regulator’s high pressure gauge will read full, between 800 – 1000 PSI.

CO2 Pressure Regulator – designed to reduce the high pressure inside of a CO2 cylinder to a lower, usable pressure that can be dispensed. The pressure-reducing regulator takes a pressure of 800-1000 PSI (pounds per square inch) from the cylinder, and regulates it, providing a controlled, reduced pressure output in the range of 1-40 PSI. Our CO2 regulators have CGA (Compressed Gas Association) 320 fittings for USA and Canada.

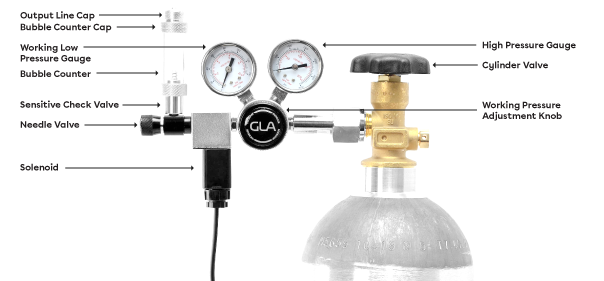

High Pressure Gauge – located at the nine o’clock position, it reads the amount of pressure present in the cylinder. As long as there is liquid gas in the cylinder the pressure will read at or around 800 – 1000psi. For CO2 cylinders, once the gauge reads in the red, the liquid gas is depleted and the cylinder should be refilled.

Working / Low Pressure Gauge – located at the twelve o’clock position, it represents the working pressure or output pressure; the pressure you are using, which can be adjusted.

Working Pressure Adjustment Knob / Screw – Adjustments to the output pressure (read on the low pressure gauge) are made with the adjustment screw or t-handle located in the center of the regulator body. The output pressure is set by turning the screw clockwise to increase the output pressure. To reduce the output pressure, the screw should be turned completely counter-clockwise.

Tank Connector Nut – attaches the regulator to the cylinder. Due to high pressure in the cylinder, this connection is a common location for leaks; it is critical to securely fasten the connector nut using the correct seal, nylon or permaseal. The connection must be tightened with a crescent wrench or CO2 wrench.

Solenoid – the solenoid is an electromechanical device that controls the flow of CO2 gas from the regulator to the aquarium. The solenoid should be connected to a timer or pH controller to control the output of CO2 into the aquarium. It is the on / off valve.

Needle Valve – the needle valve provides precise control over the amount of CO2 allowed to enter the aquarium. It allows you to fine tune and regulate the rate of flow, the number of CO2 bubbles per second. It is important to invest in a quality needle valve for increased precision and to avoid the potentially negative effects of “end of tank dumps”. As the liquid gas in a cylinder nears empty, the pressure in the cylinder will decrease, causing the output pressure to quickly increase and potentially “dump” out of the cylinder into the aquarium. A needle valve will control this “dump” because it functions as the gateway that controls the volume of gas entering the aquarium, it will stabilize the increased output pressure at the set rate of flow (bubbles per second) preventing the CO2 from completely dumping into the aquarium.

Bubble Counter – a visual tool in measuring the number of bubbles per second entering the aquarium. A bubble counter allows you to count the exact number of bubbles per second so that fine adjustments can be made to the rate of flow.

Understanding the Aquarium CO2 System

Setting up a complete CO2 system for the first time can be a little intimidating, we hope that this post will help answer some questions and alleviate a little of the mystery involved before you get started. We know you can do it, and we are here to answer questions and help you feel confident in aquarium CO2.

The CO2 Pressure Regulator

The CO2 regulator reduces the high pressure inside of a CO2 cylinder to a lower, usable pressure that can be dispensed into the planted aquarium. The pressure reducing regulator takes a pressure of 800 – 1000 PSI (pounds per square inch) from the CO2 cylinder, and regulates it to provide a controlled, reduced pressure output in the range of 1 – 40 PSI. The solenoid valve of the CO2 regulator is the powerhouse of the regulator. It is an electromechanical ON / OFF valve that controls the output of carbon dioxide gas into the aquarium.

The CO2 Cylinder

The CO2 Cylinder is a high pressure storage cylinder for carbon dioxide (CO2). Carbon dioxide in a cylinder exists primarily in the form of liquid CO2, only the head space of the cylinder contains gas. The liquid allows the cylinder to maintain a constant high pressure. Because the cylinder contains liquid gas, it must always remain in the upright position.

pH Controller

The pH controller provides a full-time, automatic pH monitoring system for the planted tank. It regulates the release of carbon dioxide, which is directly related to pH. It connects to the solenoid of your CO2 regulator and is set to a desired pH level to be maintained in the aquarium; it then signals the solenoid valve which then prompts the regulator to release or to stop releasing CO2 in order to maintain the set pH.

The controller enables you to maintain consistent and proper CO2 levels. It is an extremely valuable tool in creating a healthy and stable aquatic ecosystem. It will help your plants flourish and can decrease the level of stress to your fish by eliminating fluctuation in pH.

Automatic Timer

An automatic timer provides a more basic approach to CO2 regulation. It allows you to control your regulator and aquarium lights simultaneously and effectively. The solenoid of your regulator can be plugged into one side of a dual outlet timer and the aquarium lights can be plugged into the other side. The timer is then set to turn the regulator and the lights on in the morning at the desired time; promoting an ideal environment for plant photosynthesis. Set the timer to turn off the lights and CO2 in the evening. It’s simple, easy to use, and very useful.

Which to use, a pH Controller or Timer?

Using a timer, rather than a pH controller, can be considered a basic and inexpensive method of automating a CO2 system. On the other hand, a pH controller provides a full-time monitoring system of pH levels in the aquarium. It will regulate the release of CO2 in order to maintain a set desired pH, day and night. In comparison, using a timer versus a pH controller may save you a little CO2, because a timer shuts off the flow of CO2 gas at night when CO2 is not necessary.

It is your responsibility to monitor and adjust co2 levels in the aquarium. CO2 levels are monitored through the use of a drop checker, and through observation of the health of your fish and plants. Fine tuned adjustments to CO2 levels are made with the regulator’s needle valve, by adjusting the bubble rate, or the number of bubbles per second entering the aquarium.

The Drop Checker

Regardless of whether you decide to use a pH Controller or a timer, it’s always a good idea to use a drop checker to monitor and fine tune CO2 levels. The drop checker is a glass reservoir designed to contain an indicator solution with a known KH(Carbonate Hardness). When submerged, carbon dioxide in the aquarium is absorbed into the indicator solution, until a point of equilibrium is reached between the aquarium water and the solution. As CO2 gas is absorbed into the indicator solution, it lowers the pH of the solution, which in turn changes the solution color. This color, when compared against a pH color chart, allows you to gain an accurate perspective of the concentration of CO2 in the aquarium.

If you use a timer to automate your system, the drop checker is integral; it will be your primary measure of carbon dioxide. If you decide to use a pH controller, the drop checker is an excellent tool in helping you to determine and fine-tune the set point of your controller.

If you are introducing carbon dioxide into the aquarium via a pressurized CO2 system, it is recommended to have a drop checker. It is a good idea to always have an at-a-glance measurement of the CO2 in your aquarium.

The Check Valve

The check valve is simple and essential. It attaches in-line within your CO2 tubing and permits flow in one direction only… into the aquarium. It keeps water from back-siphoning from the aquarium into your vital components, the CO2 regulator. A complete CO2 system is not complete without it.

CO2 Resistant Tubing

The pathway through which CO2 travels to the aquarium; it completes the CO2 system, bringing it together. For this reason, it is one of the most important components of the system. It is the job of the tubing to safely deliver your precious CO2 to the aquarium. This is why it is important to invest in CO2 resistant tubing, through which CO2 is not able to escape. Silicone tubing should not be used in the planted aquarium CO2 system; carbon dioxide gas is able to permeate through the walls of silicone tubing, and is wasted. So make sure to use a CO2 resistant tubing so that your aquarium gets what it requires, efficiently, and so money is not wasted on lost CO2.

The tubing connects to the output line cap of the bubble counter, on the regulator, and travels up and into the aquarium. The check valve needs to be placed in-line, within the tubing line, between the regulator and aquarium. For those regulators without a built in bubble counter, an in-line bubble counter can be secured in-line within the tubing line so that you can accurately count the number of CO2 bubbles per second entering the aquarium. One advantage to having an in-line bubble counter is that you can place it above the aquarium stand so the bubble rate can be monitored at a quick glance.

The CO2 Diffuser

The end journey of the CO2 before it is dispersed into the aquarium water. Placed in-tank inside the aquarium or in-line in your filter tubing. It is another very important part of the complete system as it transforms and optimizes the CO2 gas entering the aquarium into a usable form of CO2. As CO2 bubbles pass through the porous ceramic of the diffuser, they are diffused into streams of tiny bubbles. With an increased surface area, these tiny bubbles can be readily dissolved into the water, increasing the overall saturation of CO2 in the aquarium ecosystem for efficient plant absorption and less waste.

It is important when selecting a CO2 diffuser to invest in one that will meet the size requirements of your aquarium. Be aware of this when selecting a diffuser for your aquarium, and consider using two diffusers, one on each side of the tank, for those larger tank setups.

Recent Posts

-

Bucephalandra: Coveted and Captivating Petite Epiphytes for Nature Aquarium

Bucephalandra aquarium plants, also commonly referred to as Buce plants, originate from the

-

Anubias: Hardy and Versatile Aquarium Plant for Every Aquascape

Anubias (family: Araceae) is an undemanding, easy plant and often one of the best suited plants for